optional. When systems operate under high pressures, extreme temperatures, or within safety-critical processes, engineers need solutions they can rely on without compromise. This is why triple offset valves have become the preferred choice for critical isolation and control duties across industries such as oil and gas, power generation, chemicals, steam and utilities.

At Heaps, we work closely with engineers, asset owners and procurement teams to specify and supply high performance triple offset butterfly valves that deliver reliability where it matters most.

What are triple offset valves and why are they used?

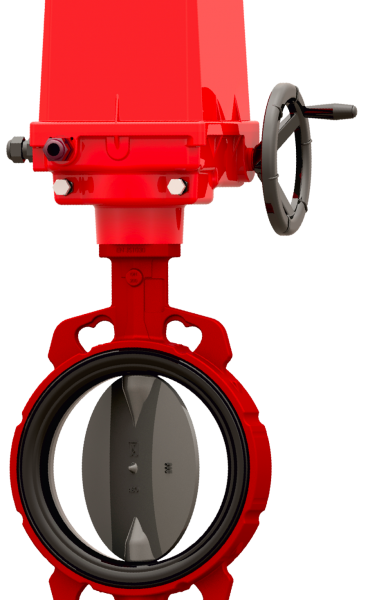

Triple offset valves are high performance butterfly valves designed for severe service applications where tight shut-off, fire safety and long-term reliability are critical. Unlike conventional butterfly valves, they use a metal-to-metal sealing principle that eliminates friction during operation and maintains sealing integrity under extreme conditions.

This design makes the valves particularly well suited to applications involving high temperatures, high pressures, thermal cycling or aggressive media, where elastomer-lined valves may struggle to perform reliably over time.

Meeting the demands of critical industrial applications

Critical applications place unique demands on valve performance. These environments often involve combinations of high pressure, elevated temperature, frequent cycling, corrosive media or strict safety requirements. In such conditions, soft-seated or elastomer-lined valves can suffer from wear, seat degradation or leakage, increasing the risk of unplanned downtime.

Triple offset valves are engineered specifically to overcome these challenges. By removing sliding contact between the disc and seat, their design eliminates many common failure modes associated with friction, wear and seal damage. This makes them a dependable choice for severe service duties where leakage or failure is not acceptable.

How valve design delivers reliable sealing

Three offsets explained

A high performance butterfly valve incorporates three distinct offsets. The first and second offsets position the shaft away from the centreline of the disc and seat, similar to a double offset butterfly valve. The third offset is the geometry of the sealing surface itself, where the disc and seat are machined into a conical profile rather than a flat plane.

Eliminating friction and seat wear

This cone-shaped geometry allows the disc to engage the seat only at the final moment of closure. As a result, the disc seals against the seat without sliding or rubbing during operation. The absence of friction during opening and closing significantly reduces wear and contributes to consistent metal-to-metal sealing over thousands of operating cycles.

In practical terms, this means lower operating torque, extended service life and reliable shut-off performance.

Performance in severe service environments

High pressure and high temperature operation

Many critical applications involve steam, thermal oil or process fluids operating at elevated temperatures and pressures. In these environments, elastomeric seats can harden, degrade or fail altogether.

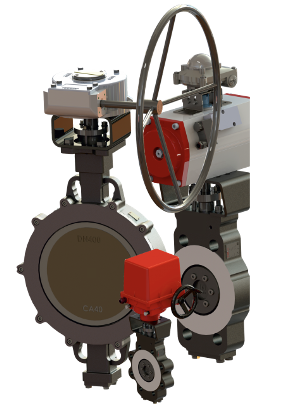

Metal seated triple offset valves are particularly well suited to these duties. The Phase Butterfly Valves 3E Series triple eccentric butterfly valves supplied by Heaps are designed for operation in very demanding environments where high safety, trouble-free operation and minimal maintenance are required. Their triple eccentricity design enables efficient sealing across a wide range of pressures and temperatures.

In steam isolation systems, where repeated thermal cycling is common, triple offset valves are often specified to maintain consistent shut-off performance and avoid unplanned shutdowns.

Achieving low leakage rates

Leakage control is another key reason triple offset valves are trusted in critical applications. Precision-machined conical seat geometry allows for tight shut-off performance that meets stringent leakage class requirements.

For plant operators, this translates into improved safety, reduced energy losses and stronger environmental compliance.

Reducing maintenance risk and lifecycle costs

One of the most practical advantages of triple offset butterfly valves is their low maintenance requirement. Because there is no rubbing between the disc and seat during operation, wear is significantly reduced compared to traditional butterfly valve designs.

Over time, this leads to:

- Longer service intervals

- Lower lifetime operating costs

- Reduced unplanned downtime

- Improved predictability in maintenance planning

Triple offset Phase Butterfly valves (replacing the solent & pratt) supplied by Heaps, are designed, and manufactured for severe service applications where reliability and longevity are paramount. Their robust construction and proven sealing principles make them a dependable choice for operators looking to minimise lifecycle risk.

Where offset valves are typically specified

Across the UK and beyond, triple offset valves are commonly specified for:

- Steam isolation in power generation and process plants

- High temperature chemical processing

- Oil and gas production and refining

- Utility and energy infrastructure

- Industrial isolation duties requiring fire-safe butterfly valves

In many of these applications, engineers are not simply selecting a valve. They are making a decision that directly impacts plant safety, operational continuity and long-term cost. Triple offset valves provide confidence because their performance characteristics are well understood, proven and repeatable.

Why engineers specify Heaps for triple offset valves

At Heaps, we do not take a one-size-fits-all approach. Our role is to support engineers through the specification and selection process, ensuring the chosen triple offset valve is appropriate for the application, operating conditions and relevant industry standards.

Each solution is selected for its engineering integrity, reliability and suitability for critical service. Our team works closely with customers to understand pressure and temperature ranges, media compatibility, operating cycles and safety requirements before recommending a valve.

A long-term engineering decision

Choosing triple offset valves is not just about meeting today’s specification. It is about long-term confidence in system performance.

By eliminating friction, enabling metal-to-metal sealing and delivering consistent isolation in extreme conditions, triple offset valves help engineers design systems that perform reliably over decades, not just years.

Contact Heaps to discuss your requirements and application challenges.

Explore our range of high performance triple offset butterfly valves and engineered solutions.