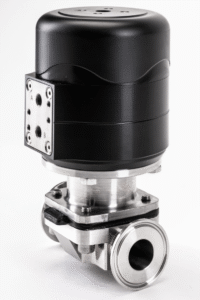

In industries where precision, reliability, and longevity are non-negotiable, selecting the right actuation technology is vital. At Heaps, we’ve developed the Phase LC Actuator, a Linear Compact (LC) actuator specifically engineered to meet the rigorous demands of sectors like oil and gas, life sciences, and nuclear. Compact, robust, and highly efficient, this actuator offers long-term performance with minimal maintenance, while maintaining absolute leak integrity under pressure.

Whether you’re upgrading from a manual valve system or specifying components for a new process line, the Phase LC Actuator represents the next evolution in diaphragm valve actuation.

LC Actuators Built for Demanding Environments

When dealing with critical processes, whether managing sterile fluids in biotech or regulating corrosive flow in petrochemicals, reliability isn’t optional. Our LC actuators are designed from the ground up to deliver consistent performance, even in the most challenging environments.

The Phase LC Actuator is suitable for Weir-type diaphragm valves ranging in size from 8mm to 50mm. It’s compatible with all diaphragm grades and is capable of delivering 100% leak-tight closure at the recommended line pressures, making it ideal for sensitive or hazardous applications where leak prevention is paramount.

Why Reliability Matters in LC Actuators

In our experience at Heaps, downtime caused by actuator failure is one of the most costly and disruptive issues for operators. That’s why every element of the Phase LC Actuator has been carefully engineered to reduce wear and extend service life:

Durable, High-Performance Materials

- Actuator Body & Cover: Acetal Resin (lightweight yet tough)

- Spindle, Namur Mount & Spool: 316 Stainless Steel for exceptional corrosion resistance

- Seals: Nitrile, with the option of Viton for increased chemical resistance

- Spring: Chrome Alloy, ensuring reliable operation over thousands of cycles

These materials have been selected to balance strength, chemical resistance, and hygienic compatibility, ensuring the actuator remains reliable in applications ranging from sterile pharmaceutical lines to chemical processing plants.

Key Features That Set Our LC Actuator Apart

Leak-Tight Closure as Standard

The glandless design and fully-supported spindle/compressor arrangement ensures 100% leak-tight closure, regardless of diaphragm type. This design significantly reduces the risk of emissions or product contamination.

Minimal Maintenance, Maximum Efficiency

Our LC actuator provides high efficiency with minimal wear, thanks to the carefully balanced internal spring and direct-mount construction. For operators, this means less time spent on inspection and repair, and more on productive uptime.

Compact, Hygienic Design

A smooth-profile actuator body makes the Phase LC easy to clean and suitable for hygienic environments, including food, beverage, and pharmaceutical manufacturing. The autoclavable stainless steel housing option enhances its suitability in sterile production zones.

Direct Mounting & Retrofit Compatibility

The actuator is directly mounted to diaphragm valves, eliminating alignment issues between actuator and valve. Whether you’re building new systems or retrofitting existing manual valves, the Phase LC makes integration straightforward and efficient. It can be installed in-line or within a workshop setting.

Versatility in Actuation and Configuration

Every operation is different. That’s why we’ve built flexibility into the Phase LC Actuator:

- Modes of Operation: Air Open, Fail Closed, or Double Acting

- Position Indication: Built-in for easy status checks

- Accessory Mounting: Four dedicated mounting holes for optional LC Switchbox

- Namur Interface: 1/8” BSPP ports (NPT available) for solenoid operation

This configurability makes the LC actuator a reliable solution across multiple process scenarios, from cleanroom environments to offshore rigs.

Supporting Critical Industries With Confidence

Oil & Gas

Where safety and environmental regulations are paramount, the LC Actuator’s leak-free operation and corrosion-resistant construction offer confidence in every cycle.

Life Sciences & Biopharma

In sterile environments, hygienic design, autoclavability, and compatibility with all diaphragm types ensure processes remain safe, validated, and contamination-free.

Nuclear & Utilities

In high-risk or high-integrity environments, equipment must endure without compromise. The Phase LC’s long life span and fault-tolerant design are ideally suited to nuclear decontamination systems, water treatment plants, and clean energy facilities.

Choose the LC Actuator Built for the Long Haul

At Heaps, we believe that automation solutions should be reliable, precise, and easy to maintain. With the Phase LC Actuator, you get a compact, lightweight actuator engineered for performance in the world’s most demanding industries. Whether you’re in oil and gas, life sciences, or nuclear energy, our LC actuator is built to deliver, cycle after cycle, year after year.

Ready to upgrade your valve automation?

Explore the Phase LC Actuator or get in touch with our technical team to discuss your project.