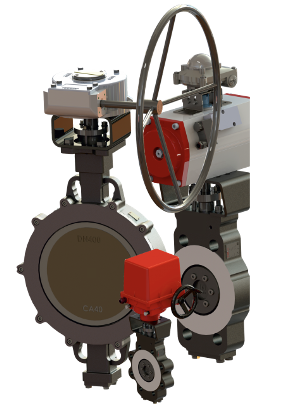

KTM, a renowned brand under Emerson, has been a pioneer in the valve industry for over 80 years, known for its premium manual and automated ball valves and actuators. KTM’s comprehensive product line, including process floating and trunnion-mounted ball valves, as well as metal-seated, high-speed, and powder discharge ball valves, caters to a wide range of applications in the oil and gas, petrochemical, and chemical industries.

Exploring KTM Ball Valve Series

KTM Series EB7 Unibody Floating Ball Valve

The KTM Series EB7 Unibody Floating Ball Valve is designed to meet the stringent requirements of the oil, gas, petrochemical, and chemical industries. Its features include:

- Conformance to ASME B16.34, API 608, and ISO 17292 standards.

- Optional testing to API 6D / ISO 14313 for enhanced reliability.

- Fire tested to API 607 6th edition for safety compliance.

- Available in carbon steel or stainless steel body, with a precision 316 stainless steel ball as standard.

- Anti-static device and blowout-proof shouldered stem for added security.

The specifications of the KTM Series EB7 Unibody Floating Ball Valve cover certifications, end connections, applications, body design, material, pressure class, process connection type, seat/seal type, shutoff class, standards, valve size, and type.

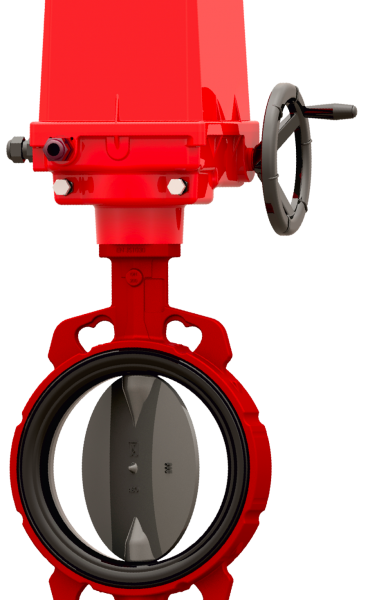

KTM Series EF190FE Two-piece Full Bore Ball Valves

The KTM Series EF190FE Two-piece Full Bore Ball Valves are designed for demanding process applications where fire-safe and fugitive emission compliance is mandatory. Key features include:

- Full compliance with ASME B16.34 and EN 12616-1 standards.

- Fire Tested and Certified to API 607 and ISO 10497 for safety assurance.

- Double stem seal design complies with ISO 15848-1 Class BH C03 requirements for reliability.

- Available in carbon steel or stainless steel body materials, offering versatility and durability.

Similar to the previous series, the specifications cover certifications, end connections, applications, body design, material, pressure class, process connection type, seat/seal type, shutoff class, standards, valve size, and type.

Applications of KTM Ball Valves

KTM ball valves find extensive use in various industries due to their versatility, reliability, and compliance with industry standards. Some common applications include:

- Evaporators & Recovery Boiler

- Facilities & Process Utilities

- Enhanced Oil Recovery

- Waste to Energy

- Dryers & Evaporators

- Distillation & Fractionation

These valves are suitable for managing liquids, liquid propane, light oil, hot water, and natural gas, making them essential components in diverse industrial processes.

KTM ball valves, offered by Heaps, are a testament to precision engineering and reliability. Their adherence to industry standards, extensive product variants, and robust construction make them indispensable for critical applications in the oil and gas, petrochemical, and chemical industries. Whether it’s the unibody floating ball valve or the two-piece full-bore ball valves, KTM’s commitment to safety, performance, and compliance shines through in every product, making it a trusted choice for industrial fluid control needs.