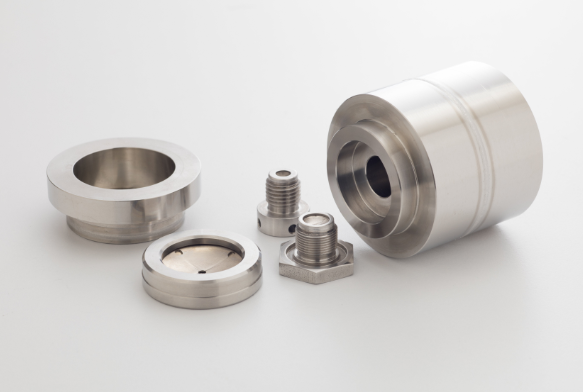

Description

Custom Engineered Discs

What We Offer

1. Sizes, Pressures & Temps

During the last 75 years we’ve protected unique applications requiring rupture discs of extremely small (⅛”) and large sizes (42”), lighter materials, corrosion-resistant materials and extreme burst pressure and temperatures. Other critical factors including response time and leakage requirements are all examined to meet your specific needs.

2. Materials

Each application has unique temperature and chemical requirements which typically dictates the material offering. Fike offers standard materials (stainless steel, nickel, Inconel®, Monel®) for normal processes and more specialized materials (tantalum, Hastelloy®, titanium, gold, silver, brass) for processes which are more challenging on standard materials or may require corrosion resistance.

3. Applications

We’ve engineered solutions for aerospace and military applications, MRI coolant lines, hydrogen applications, water filtration machines, downhole oil tools and many other challenging situations. If you represent an original equipment manufacturer or industrial process, we are ready to fulfill any of your unique needs.

4. Testing & Validation

Fike’s comprehensive Test Lab allows us to simulate various customer-specific applications and processes including cyclic conditions, back-pressure and vacuum, and non-fragmentation. The lab is equipped with cycle testers, leak-testing equipment, environmental chambers, an ASME-certified flow test rig, test tooling in a large range of sizes and volumes, and more – all used to ensure product reliability.