Description

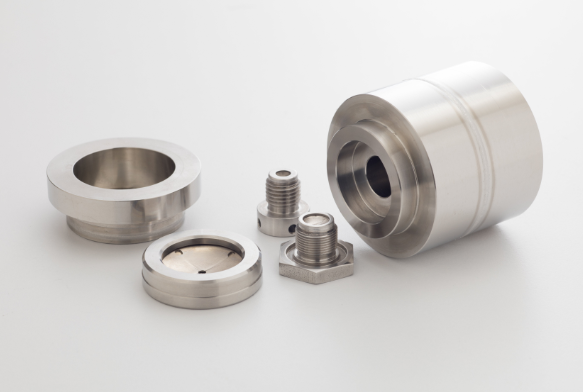

Rupture Discs For Pressure Relief

Overpressure can result in devastating events, which is why Fike rupture discs have been trusted for more than 75 years to “burst” precisely when called upon to relieve pressure and protect workers and businesses from a potential disaster.

Fike offers numerous types of rupture discs to ensure the most reliable pressure relief solution in every application: vapor or liquid media, high or low pressures, hygienic requirements, and more.

Premium Rupture Discs

- RD500 Atlas®

- Offers burst pressures up to 1500 PSIG (103.42 BARG) and sizes up to 42″ while still featuring 95/100 (ASME/EN ISO 4126-2) percent operating ratio, liquid or vapor service, back-pressure resistance and unrivaled cycling capability.

- 95% of marked burst pressures over 40 psig (2.76 barg) – ASME

- 95% of minimum burst tolerance for burst pressures less than or equal to 40 psig (2.76 barg) – ASME and EN ISO 4126-2

- 100% of minimum burst pressure over 40 psig (2.76 barg) – EN ISO 4126-2

- RD520 Axius®

- Designed for use in the most challenging industrial pressure relief applications, the reverse-acting, problem-solving RD520 AXIUS rupture disc is available in a range of corrosion-resistant materials and has the tightest burst tolerances available.

- 95% of marked burst pressures over 40 psig (2.76 barg) – ASME

- 95% of minimum burst tolerance for burst pressures less than or equal to 40 psig (2.76 barg) – ASME and EN ISO 4126-2

- 100% of minimum burst pressure over 40 psig (2.76 barg) – EN ISO 4126-2

- RD540 Ultra Low Pressure

- First high-performance metallic rupture disc for use in very low-pressure applications such as glass lined reactors.

- Ideal replacement for graphite rupture discs.

- 90% Operating Ratio