Description

KTM was the world’s first supplier of full-bore, split-body ball valves and pioneered soft- and metal-seated valves. Today, the comprehensive product line, including process floating and trunnion-mounted ball valves and metal-seated, high-speed, and powder discharge ball valves, fits almost all applications in the chemical, petrochemical and oil and gas industries.

KTM Series EB7 Unibody Floating Ball Valve – KTM Fire-safe and Anti-Static ASME 150/300 one piece, end entry, flanged ball valve for oil, gas, petrochemical and chemical industries.

Features:

- Designed to ASME B16.34, API 608 and ISO 17292.

- Optional testing to API 6D / ISO 14313.

- Single piece end entry body design complies with ASME B16.34.

- ISO 5211 top mounting flange.

- Face to Face to API 6D/ASME B16.10/BS 2080/BS EN 558.2.

- Fire tested to API 607 6th edition.

- Flange connection to ASME B16.5 as standard.

- One piece body offers total pipe integrity minimizing the number of potential leak paths.

- Carbon steel or stainless steel body as standard.

- Precision 316 stainless steel ball as standard.

- Blowout proof shouldered stem.

- Anti-static device.

Specifications:

- Certifications – Regional, PED, CE

- End Connection – Flanged

- Application – Evaporators & Recovery Boiler, Facilities & Process Utilities, Enhanced Oil Recovery, Waste to Energy, Dryers & Evaporators, Distillation & Fractionation

- Body Design – Long Pattern, Short Pattern, Side Entry

- Material – Carbon Steel, 316 Stainless Steel

- Pressure Class – ASME

- Process Connection Type – CL300RF, 300RF, CL150RF, 150RF, Flanged

- Seat/Seal Type – Ball, Soft Seal

- Shutoff Class – API 598, Zero Leakage

- Standards – API 608, ASME B16.34

- Valve Size – NPS 1/2 / DN 15, NPS 2 / DN 50, NPS 1-1/2 / DN 40, NPS 1 / DN 25, NPS 3 / DN 80, NPS 8 / DN 200, NPS 6 / DN 150, NPS 4 / DN 100, NPS 3/4 / DN 20

- Valve Size Standard – NPS, DN

- Valve Type – Floating Ball Valve, Ball

- Media – Liquids, Liquid Propane, Liquid, Light Oil, Hot Water

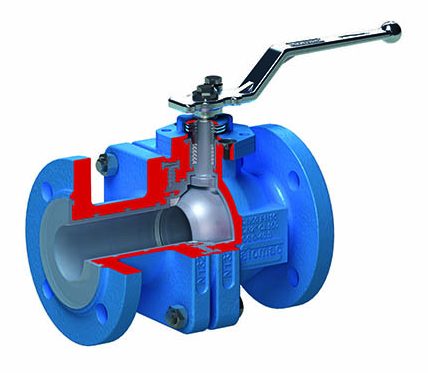

KTM Series EF190FE Two-piece Full Bore Ball Valves – High performance two-piece ball valve for demanding process applications where fire-safe and fugitive emission compliance is mandatory

Features:

- The design includes two piece split body valve design with flanged connections

- Full compliance to ASME B16.35 and EN 12616-1

- Valve pressure rating: ASME Class 150/300, DIN PN 10/16/25/40

- Size range DN 15 to DN 300 (NPS ½ to NPS 12)

- Fire Tested and Certified to API 607 and ISO 10497

- Double stem seal design complies with ISO 15848-1 Class BH C03 requirements (2500 cycles including thermal cycles)

- Double Body Seal including PTFE primary seal and secondary graphite fire safe seal

- Carbon steel or stainless steel body materials

- Standard ball valve with respect to the PAS1085 specification Class D

- ISO 5211 / EN 15081 top mounting plate available with male centering for easy actuation

Specifications:

- Certifications – SIL capable, NACE, PED, CE, Fire Safe, Fugitive Emission

- End Connection – Flanged

- Application – Burners, Burner Management Systems , Bulk Storage, Brewing, Boilers, Boiler, Blower, Biofuels, Beverages, Batch , Balance of Plant, Asphalt Blending

- Body Design – Long Pattern, Short Pattern, Side Entry

- Material – Carbon Steel, 316 Stainless Steel

- Pressure Class – PN, ASME

- Process Connection Type – 300RF, CL150RF, CL300RF, Flanged, PN16, PN25, 150RF, PN40

- Seat/Seal Type – Soft Seal, Ball

- Shutoff Class – API 598, Zero Leakage

- Standards – API 608, ASME B16.34

- Valve Size – NPS 3 / DN 80, NPS 2 / DN 50, NPS 12 / DN 300, NPS 1-1/2 / DN 40, NPS 10 / DN 250, NPS 1/2 / DN 15, NPS 1 / DN 25, NPS 3/4 / DN 20

- Valve Size Standard – NPS, DN

- Valve Type – Floating Ball Valve, Ball Valve

- Media – Liquid Propane Gas, Liquids, LPG, Mineral Oil, Natural Gas