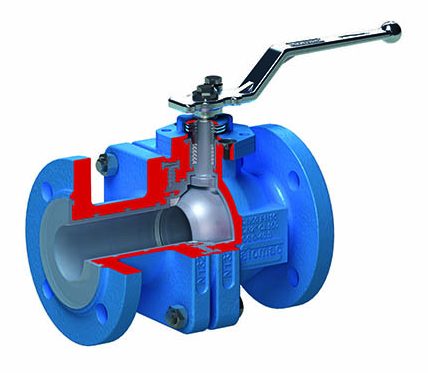

Description

The lower torque of XLB lined ball valve designs permits use of smaller actuators, allowing cost reductions and creating space saving opportunities.

Features And Benefits:

- Lower torque smaller actuators, reduced costs, space and weight saving.

- Compact design allows installation in space restricted areas in parallel piping systems.

- Actuator mounting fully compliant with ISO 5211 allowing use of standardized mounting kits.

- The SX seal in the XLB valve moves in conjunction with the spherical portion of the stem, maintaining a constant seal.

- The body assembly has metal-to-metal connection that offers resistance against forces that may be created in the pipework.

Technical Details:

- DESIGN FEATURES

- All wetted components are fully lined with permeation resistant PFA material as a barrier to corrosion.

- SIZE RANGE

- ½“ / DN 15 through; 6“ / DN 150 Full Port; 1½” through 8″ Standard Port

- Other sizes available up to 12“ / DN 300

- PRESSURE RATINGS

- PN 16, Class 150

- TEMPERATURE RANGE

- ASME: -20°F (-29°C) to 400°F (204°C)

- EN: -10°C (14°F) to 204°C (400°F)

- Above data is for ductile iron lined valves, see pressure temperature ratings in our Technical Datasheet brochure for extended temperature capabilities with alternative materials

Applications:

- Chlorine

- Benzene

- Bromine

- Sulfuric Acid

- Nitric Acid

- Hydrochloric Acid

- Phosphoric Acid

- Sea Water