General Service Butterfly Valves: Understanding General Service Butterfly Valves

At Heap & Partners, we know that reliability and efficiency are at the heart of every process system. That’s why General Service Butterfly Valves have become a go-to choice across industries looking for versatile, cost-effective flow control solutions.

General Service Butterfly Valves are the all-purpose standard for general processing applications. They are suitable for use with air, steam, water, and other chemically inactive fluids or gases, making them ideal for a wide range of operations. Their simple, compact design allows for efficient flow regulation and tight shut-off, while maintaining ease of operation and maintenance.

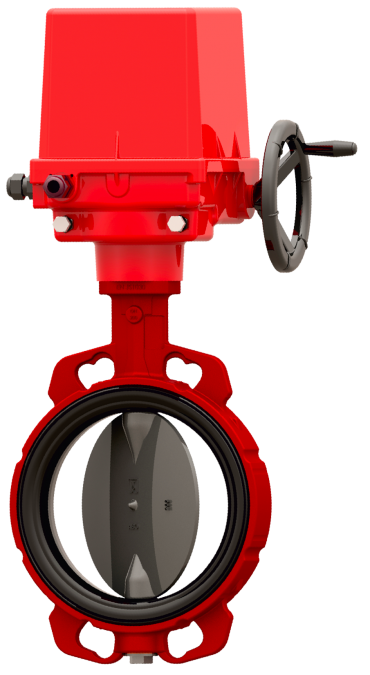

A typical General Service Butterfly Valve uses a circular disc mounted on a rotating shaft. When the valve is fully open, the disc aligns parallel to the flow, allowing an almost unobstructed passage. Turning the handle (or actuator) rotates the disc to restrict or stop the flow entirely. This straightforward mechanism makes the butterfly valve lighter and faster to operate than many other valve types, including gate or globe valves.

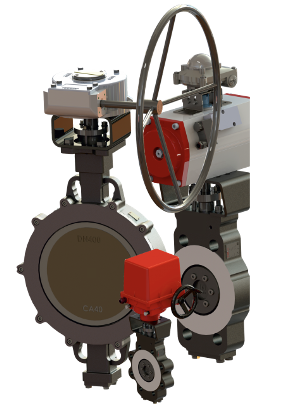

At Heaps, we supply a wide range of butterfly valves for both manual and automated operation. A 10-position handle is commonly used for manual control, while pneumatic or electric actuators can be fitted for automated on/off, throttling, or isolation control.

General Service Butterfly Valves: Construction and Design Features

One of the main reasons General Service Butterfly Valves are so widely adopted is their robust yet simple construction. The key components include the body, disc, seat, and shaft – each engineered for durability, precision, and chemical resistance.

Many of the valves in our range, such as the CENTER LINE® RS, Keystone GRW, and Phase 900 Series, incorporate resilient seated designs that ensure tight sealing and long service life. These valves are designed for reliability in both vacuum and pressure conditions and can operate effectively in temperatures ranging from -40°C up to +200°C depending on the material selection.

CENTER LINE® RS General Service Butterfly Valves offer a replaceable cartridge seat design with a solid backup ring, ensuring a vacuum-tight seal and reduced lifetime costs. With only two wetted parts, the disc and the seat, and no metal-to-metal contact, these valves deliver maximum corrosion resistance. Their self-centering disc with a spherical edge reduces wear, providing smooth operation even in severe or abrasive environments.

For applications demanding higher performance, the Keystone GRW Series provides heavy-duty construction with a resilient seat that fully isolates the body and shaft from the process medium. Primary and secondary shaft sealing prevents leakage to atmosphere, while top and bottom bearings minimise friction and torque. These valves are also available with NSF, WRAS, and DVGW approvals, making them suitable for potable water and general industrial use.

The Phase 900 Series from Heaps complements this range with concentric, soft-sealing butterfly valves available in wafer, lug, or double-flanged configurations. Designed for a wide temperature and pressure range, these valves can handle everything from potable and waste water to chemicals, gas, oil derivatives, and even food and beverage applications.

General Service Butterfly Valves vs Other Valve Types

Compared with gate, globe, or ball valves, General Service Butterfly Valves offer several advantages in terms of weight, cost, and ease of installation. Their short face-to-face dimension reduces space requirements, making them ideal for systems where compactness is key.

While gate valves are often used for full shut-off applications, they are heavier, slower to operate, and more complex to maintain. Globe valves, on the other hand, are excellent for flow regulation but can result in greater pressure drop and higher operational torque.

General Service Butterfly Valves bridge this gap by offering both control and isolation capabilities, quick quarter-turn operation, and a lower total cost of ownership. Their versatility across air, steam, and water applications makes them a standard choice in processing industries worldwide.

Common Use Case Scenarios

At Heap & Partners, we supply General Service Butterfly Valves to customers across a range of industries – from water treatment and HVAC to energy generation, chemical processing, and manufacturing.

Some common applications include:

Water and Wastewater Treatment: Reliable control of flow in pipelines handling clean or treated water.

Heating and Steam Systems: Effective isolation and throttling control in HVAC and boiler installations.

Air and Gas Lines: Smooth operation with minimal pressure loss for ventilation and compressed air systems.

Industrial Processing Plants: General purpose use in conveying non-corrosive fluids, slurries, and gases.

Because of their simple design and robust sealing, these valves are also a preferred option in bulk handling systems, beverage production, and marine installations.

Why General Service Butterfly Valves Are Cost-Effective

One of the main reasons industries choose General Service Butterfly Valves is their cost efficiency. With fewer moving parts and simplified construction, they are easier and cheaper to install, operate, and maintain than other valve types. Their lightweight design reduces the need for heavy pipe supports and makes them ideal for retrofitting or upgrading existing systems.

The replaceable seat designs, such as those found in the CENTER LINE® RS and Keystone GRW valves, allow for quick maintenance without full valve replacement. This lowers downtime and extends the overall life of the valve.

Additionally, because butterfly valves require only a quarter-turn to operate, they consume less energy when automated, making them an efficient choice for process control systems. When combined with high-quality materials such as ductile iron, stainless steel, or aluminium bronze, as found in the Phase 900 Series, the long-term value and reliability of these valves become clear.

Choosing the Right General Service Butterfly Valve for Your Application

Selecting the correct valve depends on several factors, including media type, pressure, temperature, and actuation requirements. At Heaps, our technical team can help specify the right configuration, whether wafer, lugged, or double-flanged, and ensure compatibility with your existing systems.

Our General Service Butterfly Valve range covers sizes from DN 32 up to DN 2200, with pressure ratings up to PN16 / ASME Class 150. Each model we supply is manufactured to the highest standards, tested, and certified to meet UK and international compliance requirements.

Why Choose Heap & Partners

With over 160 years of engineering experience, Heap & Partners Ltd has built a reputation as one of the UK’s most trusted valve suppliers. We work closely with leading global manufacturers to provide high-performance products that deliver reliability, safety, and efficiency across every industry sector.

Whether you require a single replacement valve or a complete system solution, our engineers can advise on selection, automation, and long-term maintenance.

Discover our full range of General Service Butterfly Valves

Visit heaps.co.uk to learn more or contact our team for expert support with your next project.