Understanding the High Performance Double Offset Butterfly Valve

At Heap & Partners, we know that choosing the correct valve for your process system is critical to performance, safety, and longevity. The High Performance Double Offset Butterfly Valve is a step up from standard general service valves, designed specifically for challenging conditions involving corrosive media, steam, or extreme temperature and pressure variations.

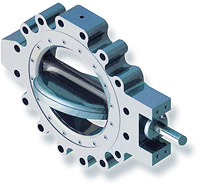

These valves feature a unique double-offset (or double-eccentric) design where the shaft is positioned slightly behind and to the side of the disc sealing surface. This geometry ensures that the disc moves away from the seat quickly as the valve begins to open, dramatically reducing seat wear and required torque. The result is a valve that offers reliable shutoff, high cycle life, and consistent performance even in demanding environments.

High Performance Double Offset Butterfly Valves can handle everything that general service butterfly valves can – and much more. Thanks to their PTFE or graphite seats, they can withstand chemically reactive or corrosive liquids, gases, and steam without deterioration. At Heaps, we supply a wide range of high performance valves from leading manufacturers such as Flowseal®, Keystone, and Phase, all engineered to deliver efficiency, durability, and safety in industrial process systems.

Key Selection Criteria for a High Performance Double Offset Butterfly Valve

When specifying the correct valve for your system, there are several important factors to consider. Each element affects performance, compatibility, and total cost of ownership.

- Size and Diameter

High Performance Double Offset Butterfly Valves are available in a broad range of sizes, typically from 2 inches up to 60 inches. At Heap & Partners, we offer Flowseal® valves up to 48 inches and Phase Series 2E valves up to DN600, with larger options available upon request. The correct diameter ensures the right flow characteristics and prevents unnecessary pressure drops in your system.

- Pressure Rating

The pressure class determines the valve’s ability to withstand system pressure without leakage or deformation. Flowseal® valves, for instance, are available in ASME Class 150 to 600, while the Phase Series 2E range extends up to 50 bar(PN40/Class 300 configurations also available). Always match the valve class to your system’s pressure requirements, allowing for operational surges and safety margins.

- Temperature Range

A major advantage of the High Performance Double Offset Butterfly Valve is its ability to handle extreme temperatures. Flowseal® valves are designed to operate between -100°F and +500°F, while the Phase 2E series can be configured for service from -55°C up to +325°C or higher depending on material selection. Selecting appropriate seat and body materials is key to long-term reliability at these ranges.

- Media Type (Liquid, Gas, Steam, or Corrosives)

The process media will directly influence valve selection.

- Liquids (water, oil, fuel): Carbon steel or ductile iron bodies with PTFE or RTFE seats are typically suitable.

- Steam or high-temperature gases: Graphite or metal-seated configurations ensure tight sealing and reduced erosion.

- Corrosive fluids or chemical vapours: Stainless steel or exotic alloys such as Duplex, Super Duplex, Monel, or Aluminium Bronze are recommended.

Heaps offers all these material configurations through its Flowseal®, Keystone, and Phase valve ranges, each tailored for specific environments including petrochemical, energy, marine, and water treatment industries.

Material Options: Body, Disc, and Seat

Selecting the right material combination is crucial to achieving maximum performance and life expectancy.

- Body Materials: Carbon steel, stainless steel, aluminium bronze, and Duplex are the most common materials for high performance designs. These provide strength, corrosion resistance, and compatibility with a wide range of fluids.

- Disc Materials: Stainless steel, Monel, and aluminium bronze discs offer high mechanical integrity and chemical resistance.

- Seat Materials: PTFE and reinforced RTFE are ideal for chemical and steam service, while Fire-Flow or graphite options are available for fire-safe and high-temperature conditions.

For example, Flowseal® valves feature a bi-directional pressure-energised sealing system that maintains tight shutoff under both vacuum and pressure. Their seat options, including TFE, RTFE, UHMWPE, and Fire-Flow, allow engineers to match sealing performance precisely to their process conditions.

Flange Types and Configurations

High Performance Double Offset Butterfly Valves are available in various body configurations to suit installation requirements:

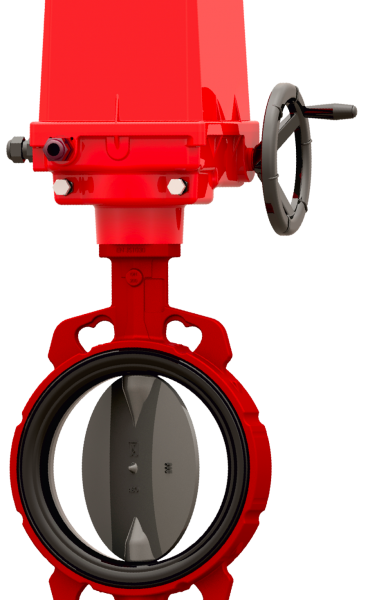

- Wafer Type: Compact and lightweight, ideal for space-constrained systems.

- Lug Type: Allows one side of the pipeline to be removed without affecting the other.

- Double Flanged: Offers added rigidity and is well-suited to heavy-duty industrial systems.

At Heaps, our Flowseal®, Keystone, and Phase valves are all available in these configurations, meeting standards such as EN 593, API 609, ASME, and PN flange ratings.

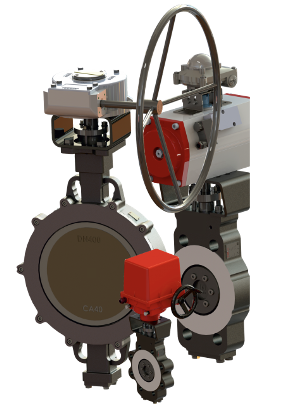

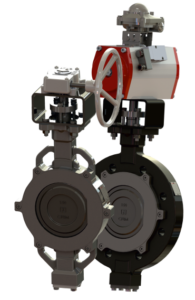

Actuation Options: Manual, Electric, and Pneumatic

Another important consideration is how the valve will be operated.

- Manual Operation: Simple and reliable, manual handles or gear operators are often chosen for smaller diameters or infrequent operation.

- Electric or Pneumatic Actuation: For automation or remote control, actuators allow quick response and integration with process control systems. Pneumatic actuators are favoured for fast cycling, while electric actuators suit applications requiring precise modulation.

All of our high performance butterfly valves are available with bare stem, handle, gear operator, or actuated configurations. Our engineering team can assist in specifying the right torque output and fail-safe options for your system.

Approvals and Compliance

Safety and compliance are critical for any valve selection. Heaps’ High Performance Double Offset Butterfly Valvescomply with a range of international standards, including ASME, EN, and API, as well as Pressure Equipment Directive (2014/68/EU) certification. Many models also carry fire-safe and ATEX approvals, making them suitable for hazardous environments.

Buyer’s Checklist: Selecting the Right Valve

Before specifying your next valve, review the checklist below to ensure the right fit for your application:

- Confirm process media type and whether it is corrosive or high temperature.

- Define pressure and temperature range requirements.

- Choose the appropriate body and seat materials for compatibility.

- Select a flange configuration that fits your pipeline design.

- Determine actuation method – manual, pneumatic, or electric.

- Check for industry approvals (PED, API, ASME, etc.).

- Verify size range and flow capacity requirements.

- Consider maintenance accessibility and seat replacement design.

Our team at Heap & Partners can help you navigate these choices to find the most efficient and reliable solution for your process environment.

Why Choose Heap & Partners

With over 160 years of engineering heritage, Heap & Partners Ltd is one of the UK’s most established suppliers of industrial valves and flow control equipment. We work with leading manufacturers to provide products that meet the highest standards of performance and durability.

From Flowseal® to Keystone and Phase, our high performance double offset butterfly valve range covers everything from water and steam systems to chemical, marine, and energy applications. Each valve is assembled, tested, and certified to guarantee the performance our customers rely on.

Discover the full range of High Performance Double Offset Butterfly Valves at Heaps.

Visit heaps.co.uk or contact our technical team for tailored advice on your next project.