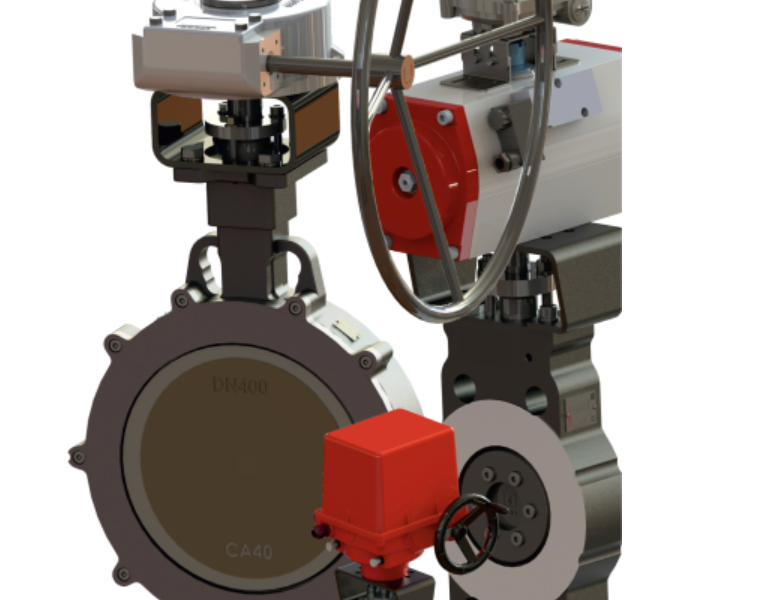

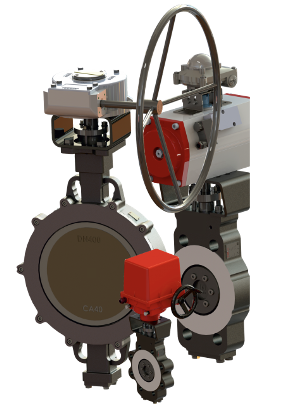

When performance, reliability, and efficiency are essential, the Phase LC Actuator provides a compact and robust solution for diaphragm valve automation across a wide range of industries. Designed and manufactured to meet the exacting demands of modern process environments, this Linear Compact (LC) Actuator combines precision engineering with ease of installation and exceptional longevity.

At Heap & Partners, we supply the full range of Phase LC Actuators, supporting applications in food and beverage, chemical, pharmaceutical, water treatment, and nuclear sectors. With a proven reputation for leak-tight performance and minimal maintenance requirements, the LC Actuator offers both technical excellence and operational efficiency.

Phase LC Actuator: Technical Overview

The Phase LC Actuator is purpose-built for use with weir-type diaphragm valves ranging from DN8 to DN50 (8 mm to 50 mm). Compact, lightweight, and durable, it replaces traditional manual bonnet assemblies with a precision-engineered pneumatic actuator that delivers 100% leak-tight closure against recommended line pressures.

Each actuator is designed for direct mounting, which eliminates misalignment between valve and actuator. This ensures consistent operation, reduced mechanical stress, and long-term sealing integrity even in demanding process conditions. The glandless design enhances reliability further by reducing the risk of hazardous emissions and minimising ongoing maintenance needs.

Key performance features include:

- 100% leak-tight closure for total process security

- High efficiency with minimal wear, supporting long service life

- Compact design for weir-type diaphragm valves

- Direct mounting to eliminate alignment errors

- Glandless construction, improving environmental and operator safety

- Visual position indication for easy operation checks

- Namur mounting plate for solenoid operation with 1/8″ BSPP ports (NPT optional)

- Four accessory mounting holes, compatible with the LC switchbox

- Suitable for all diaphragm grades, including Phase and Saunders valves

- Fully supported spindle/compressor, ensuring extended diaphragm life

- Interchangeable compressors for screw and bayonet-type diaphragms

- Air Open, Fail Closed, and Double Acting configurations available

- Retrofit capability to automate existing manual valves

- Smooth, hygienic design, autoclavable when using stainless steel housing

- Working air supply pressure: 6 bar g

This versatility allows engineers to select a configuration tailored to specific system requirements, balancing safety, performance, and lifecycle cost.

Phase LC Actuator: Materials of Construction

Every component of the Phase LC Actuator is carefully selected to ensure strength, corrosion resistance, and longevity in service.

- Actuator Body and Cover: Acetal Resin (black) for lightweight durability

- Spindle: 316 Stainless Steel, corrosion-resistant and robust

- Seals: Nitrile (optional Viton for chemical compatibility)

- Spring: Chrome Alloy for reliable actuation and long-term resilience

- Namur Mount: 316 Stainless Steel with Nitrile Gasket

- Spool: 316 Stainless Steel with clear or tapped metric/imperial holes

This material specification enables the LC Actuator to withstand harsh industrial conditions, from high-pressure chemical systems to cleanroom pharmaceutical environments.

PHASE LC Actuator in Industrial Applications

The Phase LC Actuator has been developed to serve the specific needs of multiple industries where process control, hygiene, and durability are critical. Below are some of the core applications across key sectors.

- Food & Beverage Production

In food and beverage processing, cleanliness and precision are paramount. The Phase LC Actuator’s smooth, hygienic design and autoclavable stainless-steel option make it ideally suited to CIP (Clean-In-Place) and SIP (Sterilise-In-Place) systems.

Its glandless construction prevents contamination, while direct mounting ensures consistent operation across frequent washdown cycles. Whether controlling syrup transfer, dairy filtration, or brewing systems, the LC Actuator ensures long-lasting reliability and safe operation.

- Chemical Processing

Chemical plants demand actuators that can endure aggressive media and fluctuating pressures. The Phase LC Actuator’s 316 stainless steel spindle and optional Viton seals deliver exceptional resistance to corrosion and chemical degradation.

Its 100% leak-tight closure ensures safe isolation of hazardous materials, while the compact design allows easy integration into complex pipework systems where space is limited. Maintenance requirements are minimal, supporting extended operation with reduced downtime.

- Water Treatment

In water and wastewater management systems, reliability and service life are critical to reducing operational costs. The Phase LC Actuator provides robust sealing and long cycle life, ideal for dosing, filtration, and backwash control applications.

With a working pressure of 6 bar g, it performs reliably in variable flow conditions and can be easily retrofitted to replace manual valve assemblies across treatment facilities.

- Pharmaceutical & Biotech Manufacturing

Pharmaceutical production environments require ultra-clean, precise, and reliable actuation systems. The Phase LC Actuator’s hygienic profile, autoclavable design, and leak-tight closure meet stringent cleanliness and safety standards.

Used extensively in sterile processing, purified water systems, and vaccine production lines, the actuator supports exacting process control where contamination prevention and repeatable operation are essential.

- Nuclear and Specialist Industries

In nuclear, defence, and high-integrity applications, reliability and containment are critical. The Phase LC Actuator’s glandless design minimises the risk of emission or leakage, while its 316 stainless steel components deliver durability under demanding conditions.

The ability to provide fail-safe (spring return) or double-acting operation adds flexibility for use in safety-critical systems where operational certainty cannot be compromised.

Why Choose Heaps for Your Phase LC Actuator

As one of the UK’s leading valve and actuator specialists, Heap & Partners combines deep technical knowledge with a commitment to engineering quality. Our team provides full technical support, from selection and specification to installation and maintenance.

Whether you’re upgrading existing equipment or sourcing actuators for new projects, we offer the complete Phase LC Actuator range along with all required accessories and conversion kits. We also supply pre-assembled valve and actuator packages, ensuring accurate configuration and time-efficient delivery.

Our in-house service facilities enable testing, retrofitting, and ongoing support, helping you maintain compliance, optimise performance, and extend equipment life.

The Phase LC Actuator represents the perfect combination of strength, precision, and practicality. Its compact footprint, leak-tight performance, and versatile configuration options make it an ideal choice for industries demanding reliability and long-term value.

From pharmaceutical production to chemical processing and water treatment, this actuator delivers consistent performance under the most challenging operating conditions, all supported by the trusted expertise of Heap & Partners.

Discover the full Phase LC Actuator range today at Heaps.co.uk or speak to our technical team for advice on selection, installation, and integration.