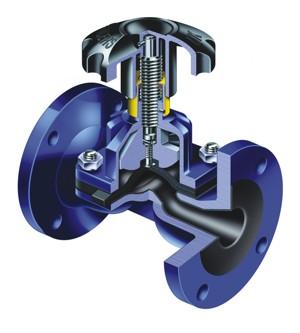

Description

Severe service control valves are used in the most difficult installations within your process plant. These installations commonly include cavitating, erosive, corrosive, noisy, high pressure, high temperature, high pressure drop, or high velocity media. To maximize longevity in these harsh conditions, severe service control valves typically utilize extremely hard materials, materials that withstand temperature and pressure extremes, bodies with special flow paths, bodies with high capacities, and cages with unique flow passages. A severe service valve may or may not be a critical service valve—one that’s essential to the operation of the plant.

Typical Applications:

- Condensate Recirculation – At the end of a steam power cycle the water is condensed back to liquid form. A centrifugal pump then moves this water through heaters back toward another pass through the boiler. All centrifugal pumps have a minimum flow rate through the pump to avoid overheating and cavitation. Valve controls bypass flow from pump outlet back to some lower pressure point, this bypass flow prevents overheating and cavitation. The valve must be selected to prevent or withstand cavitation.

- Water Injection (Water Flood) – Water injection pumps deliver large flow rates at high pressures for enhanced oil recovery. The water is injected into the oil formation at key locations to maintain the formation pressure and drive the oil toward the production lines. Careful control of the pressure and flow is required to maintain this without damaging the water-oil interface. Valve arrangements allow the bypass to either go overboard or to a produced water reservoir. Centrifugal pumps require a minimum flow rate to maintain stable operation and avoid internal cavitation. When system conditions limit the flow rate below the pump minimum, a control valve allows bypass flow to maintain the minimum flow and prevent pump damage. The valve must handle the associated cavitation potential.

- Compressor Anti-Surge – Centrifugal compressors are dynamic machines, the gas is compressed by high-speed, rotating impellers. Slow changes in flow and pressure demand can be accomplished by changing the compressor speed. Compressor inertia prevents rapid changes of the operating flow and pressure, so a special valve controls bypass flow from the compressor outlet to the inlet providing both rapid process control and surge prevention in the compressor.