Description

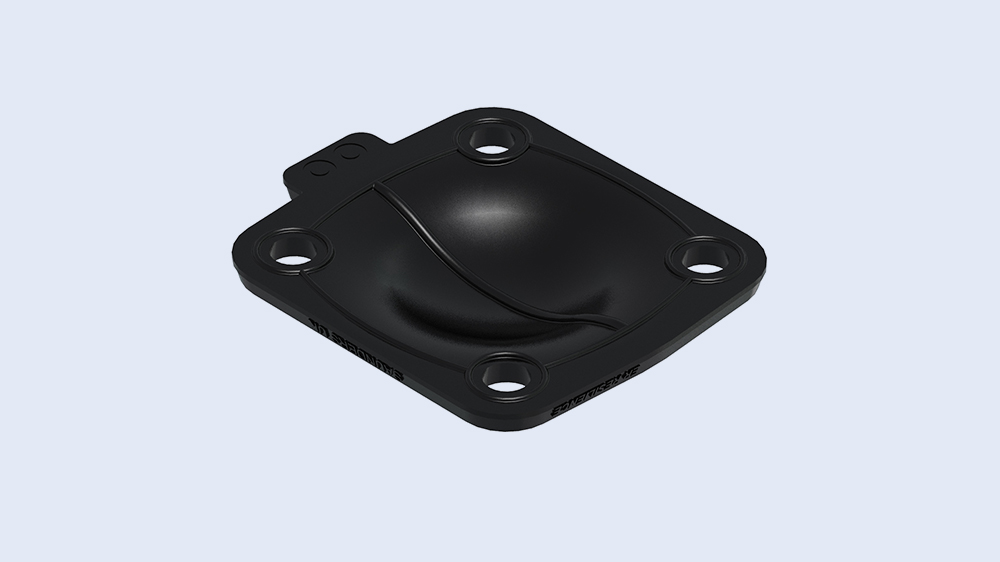

SAUNDERS® ER Resilience Elastomer Diaphragm – Saunders® elastomer diaphragms consist of a range of proprietary materials specifically developed by Saunders® team of in-house polymer technologists to meet the demands of Life Science applications.

Features And Benefits

- Excellent mechanical strength and good all round resistance to Life Science process and utility applications

- Full batch traceability provides maximum security, reliability and repeatable performance

- Organic peroxide cured for reduced extractables and leachables

- Full global compliance and testing to FDA, USP Class VI and BSE/TSE

SAUNDERS® EX Endurance Diaphragm – Saunders® EX Endurance Diaphragm is a unique material combination which offers outstanding performance in applications exposed to prolonged sterilisation regimes, or higher temperature up to 175°C (347°F).

Features And Benefits

- Outstanding high temperature performance and resistance to long term exposure at elevated temperatures

- Ideal for steam distribution and supply, sterile barrier, and block-and-bleed applications

- Improved seal-to-atmosphere performance and reduced requirements for re-torqueing of fasteners after thermo cycling

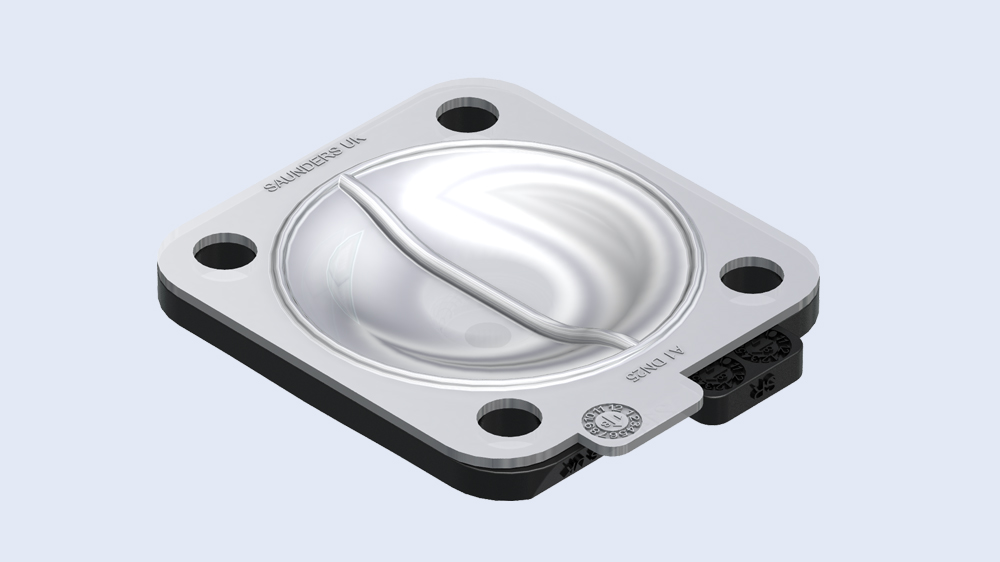

SAUNDERS® PR Pure Resilience PTFE Diaphragm – Saunders® PR Pure Resilience diaphragms are robust two piece leaf type. The design incorporates a virgin PTFE wetted face backed with a fabric reinforced support diaphragm.

Features And Benefits

- Stud anchorage is fully encapsulated to ensure maximum strength and lifetime in service

- Full batch traceability provides maximum security, reliability and repeatable performance

- Industry conforming low level of extractables and leachables

SAUNDERS® PV Passivation Diaphragm – Saunders® PV Passivation Diaphragm is a dedicated “single use” elastomer diaphragm developed for passivation service of stainless steel Biopharm systems. The design is manufactured from FDA/USP compliant elastomer and is supplied with bayonet attachment for interchangeability with Saunders® PTFE/TFM range.

Features And Benefits

- Reduced cost and TCO (Total Cost of Ownership) benefits versus single use of PTFE diaphragm

- High visibility tag reduces risk of diaphragm not being replaced after passivation

- Materials suitable for use with citric acid and EDTA-based passivation chemicals and typical post passivation clean and rinse solutions

SAUNDERS® SR Steam Resilience TFM Diaphragm – SAUNDERS Life Science Modified PTFE (TFM) diaphragms are robust two piece leaf type. The design incorporates a TFM wetted face backed with a fabric reinforced support diaphragm.

Features And Benefits

- Significant reduction in creep and deformation under aggressive sterilisation regimes

- Increased resistance to permeation compared with standard PTFE

- Full batch traceability provides maximum security, reliability and repeatable performance