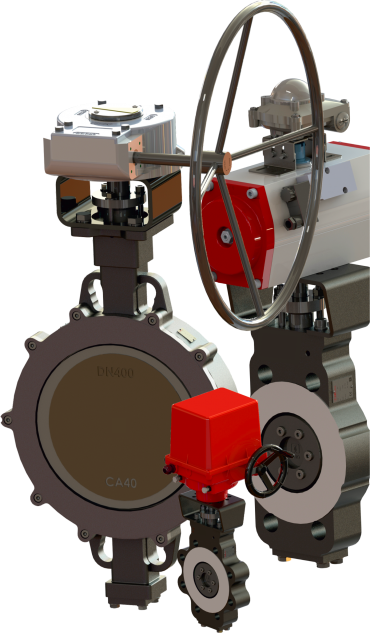

Description

Phase 3E Series triple eccentricity butterfly valves are designed for operation in very demanding environments that require high safety, trouble-free operation and minimal maintenance. The triple eccentricity design contributes to a very efficient metal-to-metal sealing principle, which is designed primarily for high parameter sealing at both pressures and temperatures. The appropriately designed geometry eliminates friction between the seating surfaces of the sealing TRIM, which aids in the longevity of the damper. The main sealing node is formed by a high precision sealing pair with a special bevelled cone geometry.

NOMINAL SIZE: DN80 – DN600

BODY TYPE: WAFER type with through holes, LUG type with threaded holes, Double flanged With through holes

WORKING PRESSURE: 25 bar / 40 bar / 50 bar

FLANGE CONNECTION: PN10 / PN16 / PN25 / PN40 / Class 150 / Class 300

WORKING TEMPERATURE: -60 °C / +500 °C

WORKING MEDIA: Waste and supply water, Potable water, Hot industrial water, Petroleum products, Fuel, Oil, Oil derivatives, Pulp, Paper stock, Gas, Steam, Condensate, Air, Bitumen (asphalt), ect.

TIGHTNESS: Class A/B

BODY MATERIAL:

Low carbon steel 1.1156 (A352 LCC) / 1.0566

Low carbon steel 1.0566 + stellite

Carbon steel 1.0625 (A216 WCB) / 1.4025

Carbon steel 1.4025 + stellite

Stainless steel 1.4408 (A351 CF8M) / 1.4401 (AISI 316)

Stainless steel 1.4401 (AISI 316) + stellite

ATEX and TA-luft seal on request

Exotics including Duplex, Super Duplex, 6Mo and Aluminium Bronze available on request