Description

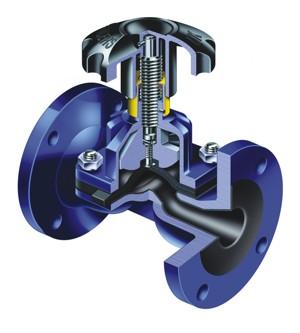

Superior Sealing for Chemical and Abrasive Processing Applications

- The Science Inside: Proprietary diaphragm technology provides exceptional sealing and complete emissions control.

- Unmatched Experience & Innovation: A comprehensive selection of polymers delivers superior corrosion and abrasion resistance for a wide range of demanding applications, since 1928.

- Efficient Operation: Top Entry design enables in-line maintenance to reduce plant downtime

| Lining | Chemical name | Body material | Size | Temperature |

|---|---|---|---|---|

| PFA | Perfluoralkoxy | SG Iron | DN15 – DN200 | -10 Deg C to 175 Deg C |

| ETFE | Ethylene Tetrafluoroethylene | SG Iron | DN15 – DN150 | -10 Deg C to 150 Deg C |

| PVDF | Polyvinylidene Fluoride | SG Iron | DN15 – DN150 | -10 Deg C to 125 Deg C |

| PP | Polypropylene | SG Iron | DN20 – DN150 | -10 Deg C to 85 Deg C |

Our Metal bodies provide simultaneous mechanical support for the linings and protection against Ultraviolet (UV) attack. The nominal bore thickness of Saunders linings range from 1 to 5.5mm depending on lining material and valve size: Glass 1mm, Rubber 2 – 4.5mm, Plastic 4 – 5.5mm.

NOW AVAILABLE!

Plastic Lined Bodies with Stud Design

The new stud design replaces sizes DN20-DN50 through bolt design with a fixed stud in the body. This is the same design as we have on our larger sizes (DN65 onwards)

There are many benefits, such as:

- Safer for maintenance engineers as they will only require one tool to disassemble and reassemble the valve in a range of environments

- Upto 50% reduction in change out time as less components are required to be held during the maintenance procedure

- Extended diaphragm life due to the studs acting as a guiding pins, ensuring correct diaphragm centralisation on every maintenance cycle

Since P.K. Saunders invented the original diaphragm valve in 1928, Saunders® has led the way in providing solutions to industries where flawless operation and resistance to corrosion, abrasion and contamination are imperative.

As we enter next decade, Saunders® IDV team is gearing up to provide new product solutions to meet ever increasing customer needs based on 5 key elements which are centre stage of Crane business philosophy:

- Product Safety

- Product Quality

- Delivering best in class Performance

- Total Cost of ownership

- Profitable Growth through reduced equipment downtime