The Saunders IDV diaphragms are changing and will be known as the eXtreme range. The table below outlines the changes in terms of the diaphragm grade, and also, the diaphragm material.

The older, existing, diaphragm grades will be rationalised from the IDV diaphragm range and will become obsolete from 31st March 2020. In the interim we will have both grades and the material in the description but only the grades on the packaging i.e. ‘XB (300) Diaphragm’.

The Saunders® eXtreme elastomer range will provide reliable and cost effective solutions in a wide range of applications and Saunders® high performance PTFE range will cater for highly demanding chemical processes. The new addition in the range is diaphragm grade ‘KC’ (three-layer Chlorine diaphragm), specifically aimed at highly aggressive Chlorine applications. This diaphragm comprises of PTFE facing with a PVDF interlayer and backing of FKM material, with a titanium stud, which offers enhanced corrosion resistance, resulting in an extended life with reduced downtime in the Chlor Alkali industry. These grades are for industrial applications and therefore will not carry FDA/USP6 certification. If certification is a requirement the HC4 diaphragm range must be requested.

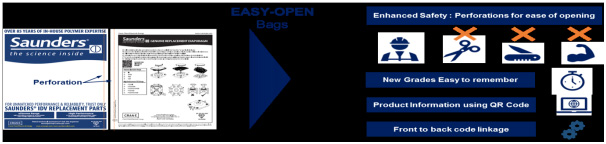

Apart from ensuring high quality performance, Saunders IDV spare diaphragms will now be available in new EZOPEN recyclable bags, which will minimise the need for the use of any sharp objects or physical effort. The purpose is to enhance safety at the work place, reduce the opening time, and also prevent diaphragm damage during the process. The QR code provided on the diaphragm bag will aid in easily obtaining technical information as well as recommended applications.