Description

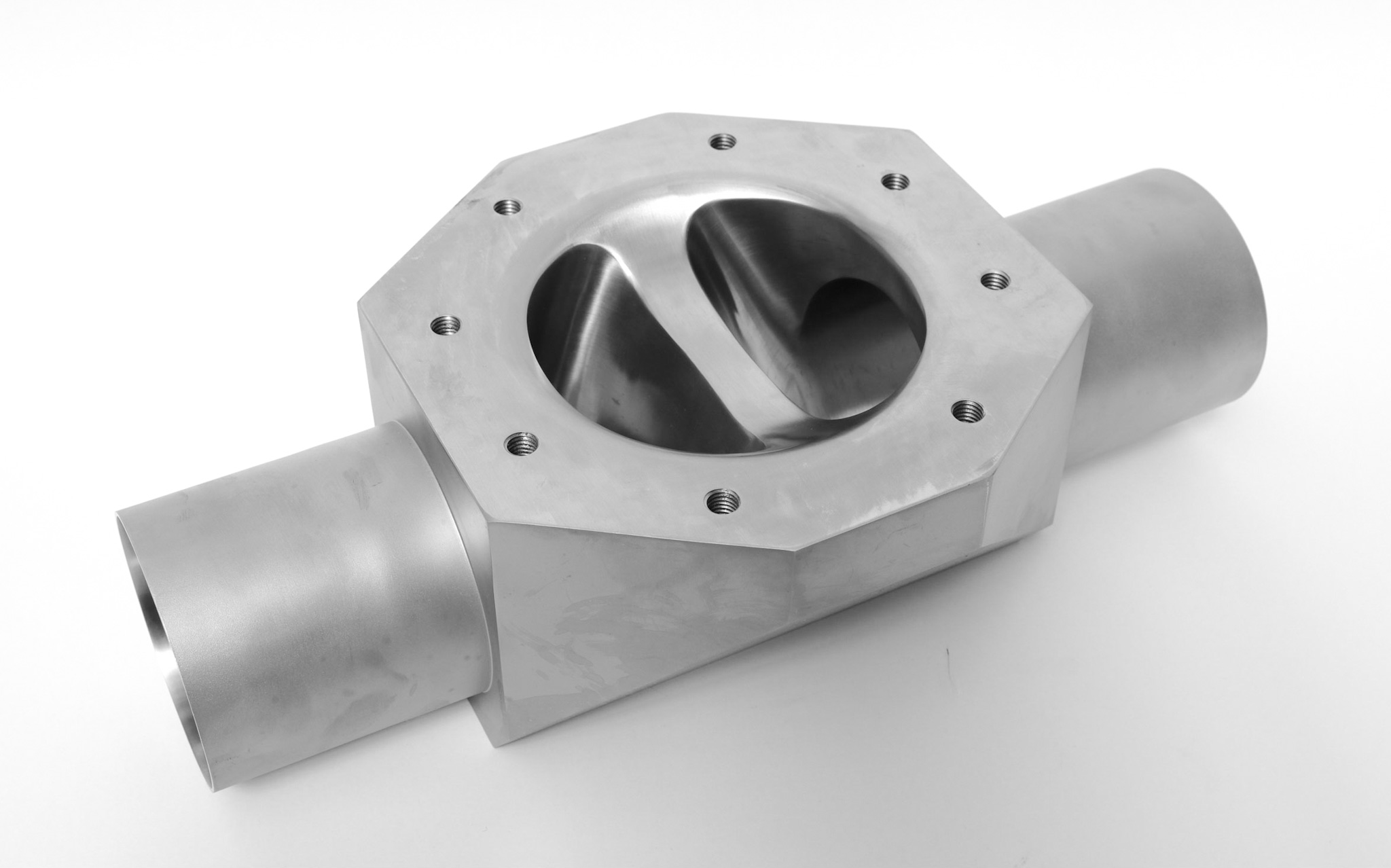

Standard 2-Way Bodies

The standard 2-way valve body is the basic building block of diaphragm valve technology. Phase 2-way forged bodies are manufactured from wrought 316L/1.4435 stainless steel bar. Exotic/Special alloys are also available on request.

The standard 2-way valve body is the basic building block of diaphragm valve technology. Phase 2-way forged bodies are manufactured from wrought 316L/1.4435 stainless steel bar. Exotic/Special alloys are also available on request.

The forging process results in a homogeneous surface that is free of defects such as porosity, inclusions, or shrinkage cavities. This defect-free surface is an ideal substrate for the high levels of mechanical and electropolished surfaces demanded by the clean processing industries to maintain sterility and optimize cleaning processes. Phase forged bodies are manufactured to achieve low ferrite levels of less than 0.5% maximum. This reduces the potential for migration of oxides through a high purity water system.

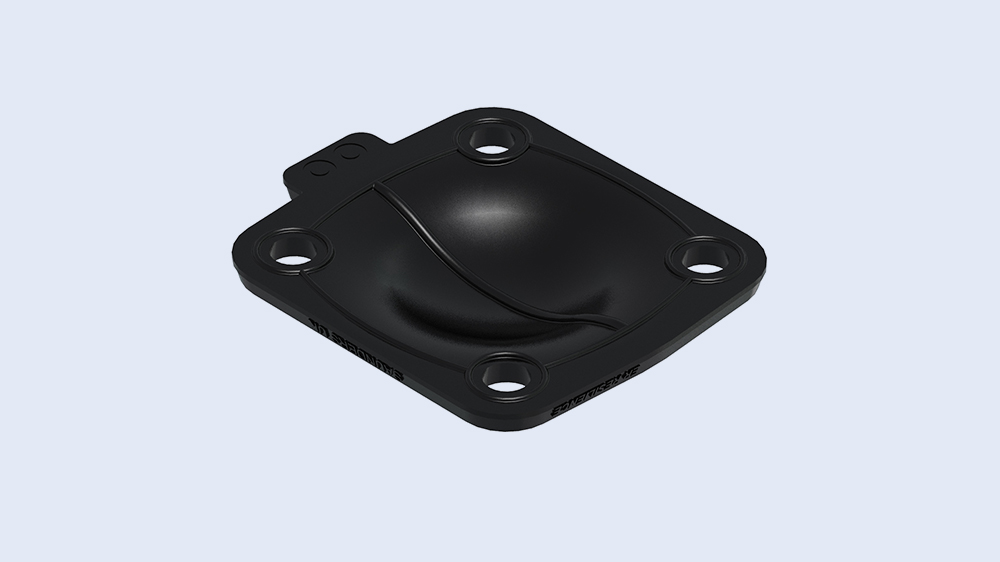

Valve Body Features:

• Cavity-free and self-draining

• Readily incorporated into valve cluster and access valve fabrications

• Materials of construction and surface finish compatible with industry standards system requirements

• Bi-directional flow path

• Full traceability to EN 10204 3.1 and ASME BPE

• Exotic/Special alloys are also available on request

Machined from Solid 2-Way Valve Bodies (DN100-DN150/4.00”- 6.00”)

Larger size designations are machined from solid wrought stainless steel bar stock. This construction brings the same high level of surface integrity and metallurgical security as available with the 2-Way forged bodies.

Forged Body Features:

• Unique Body Flats to indicate self drain angle

• Integral weld and hygienic clamp ends

• Controlled sulphur, 0.005%-0.017 per ASME BPE Standard

• Exotic/Special alloys are also available on request