Description

Extended life, reliability, safety and ease of use, combined with an essentially simple design, facilitate low maintenance and minimal running costs. When subjected to both pressure and vacuum, Saunders® diaphragm valves operate and close 100% leaktight. This feature reduces processing and handling costs by cutting out the waste normally associated with conventional valve designs.

Saunders offers a full range of diaphragm selections engineered to meet the exacting demands of our industrial customers. All grades of rubber and PTFE have been developed to suit individual customer requirements and are proven, even in the most arduous environments.

All Saunders diaphragms are made from high quality materials and are manufactured in-house to strict quality standards. This is borne out by the fact that all diaphragms are fully traceable in accordance with EN10204 3.1. This gives our customers the assurance of consistent, reliable and repeatable quality resulting in consistent, reliable and repeatable process performance.

To assist in the selection of the best diaphragm materials please use the Saunders material selection program or alternatively, please feel free to contact our customer service group, who will be happy to assist you with the best recommendation for your application.

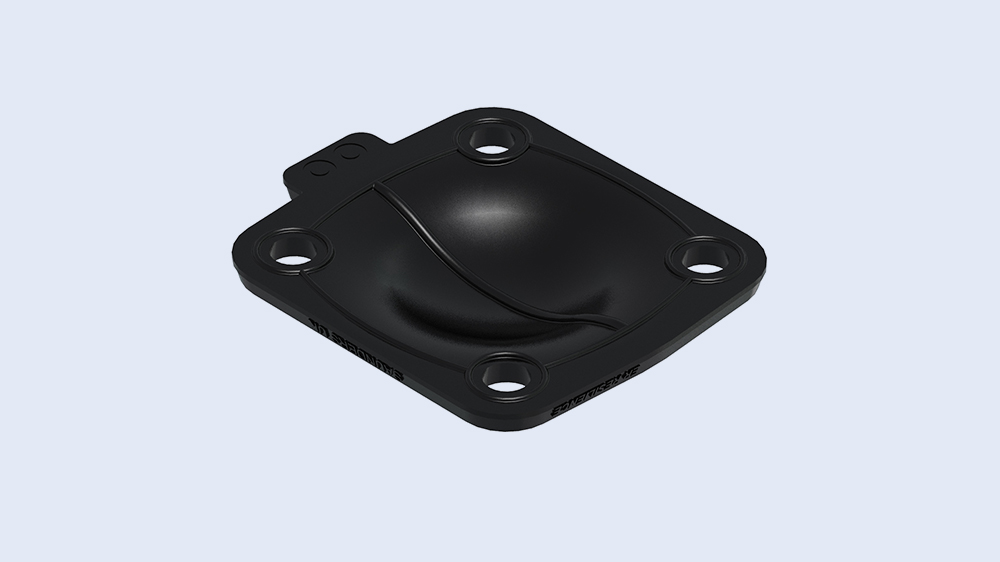

SAUNDERS® eXtreme Elastomer Diaphragm Range (XB, XC, XE, XF) – The Saunders® eXtreme eslastomer diaphragm is an intricate deisgn and not a simple moulded part. Layers of proprietary blended and calendared (rolled into sheet form)rubber is vulcanized with high strength woven reinforcement.

Features And Benefits

- Diaphragms constructed with multiple layers of rubber and fabric reinforcement for optimised flex performance, even in high-cycle applications

- Sealing ribs on the diaphragms wetted face provide enhanced leak tight sealing capabilities and lower closure torques

- Proprietary formulations, solely manufactured in-house, deliver the necessary physical properties to provide excellent abraison and corrosion resistance

Technical Details

- SIZE RANGE

- XE and XB A Type: DN008 – DN350

- XC A Type: DN015 – DN350

- XF A Type: DN65

- KB Type: DN015- DN350

SAUNDERS® High Performance PTFE Diaphragms (PB, PC, PE) – Saunders® IDV High Performance PTFE Diaphragms are a robust two piece leaf type design incorporating a virgin PTFE wetted face with a fabric reinforced elastomer support backing.

Features And Benefits

- Unique stainless steel bayonet fitment; reduces point loading, improves sealing performance and facilitates correct diaphragm installation

- Third generation two-piece construction increases pressure rating and enhances durability, providing a longer diaphragm lifetime

- 100% virgin PTFE contact face is chemically inert, offering improved corrosion resistance and extending diaphragm lifetime in the most aggressive of services

Technical Details

- SIZE RANGE

- A Type: DN015 – DN250

SAUNDERS® Standard Diaphragm Ranges (HT, C, Q, AA, 237)

Features And Benefits

- Premmium grade raw materials and fabric reinforcement in a multi-layer contruction providing maximum performance and durability in the most demanding applications

- Studs attached with bonding adhesive and mechanical anchorage providing strength and durability for intensive and systematic mechanical operation

- Dual sealing ribs (across the weir and around the diaphragm periphery) to provide enhanced leak tight sealing capabilities and lower closure torques

Technical Details

- SIZE RANGE

- A Type: DN008 – DN350

- KB Type: DN015- DN350

- TEMPERATURE RANGE

- Saunders® HT Neoprene –30 °C to 100 °C

- Saunders® C Nitrile –20 °C to 100 °C

- Saunders® Q & AA Natural Rubber –50 °C to 100 °C

- Saunders® 237 Hypalon –10 °C to 100 °C